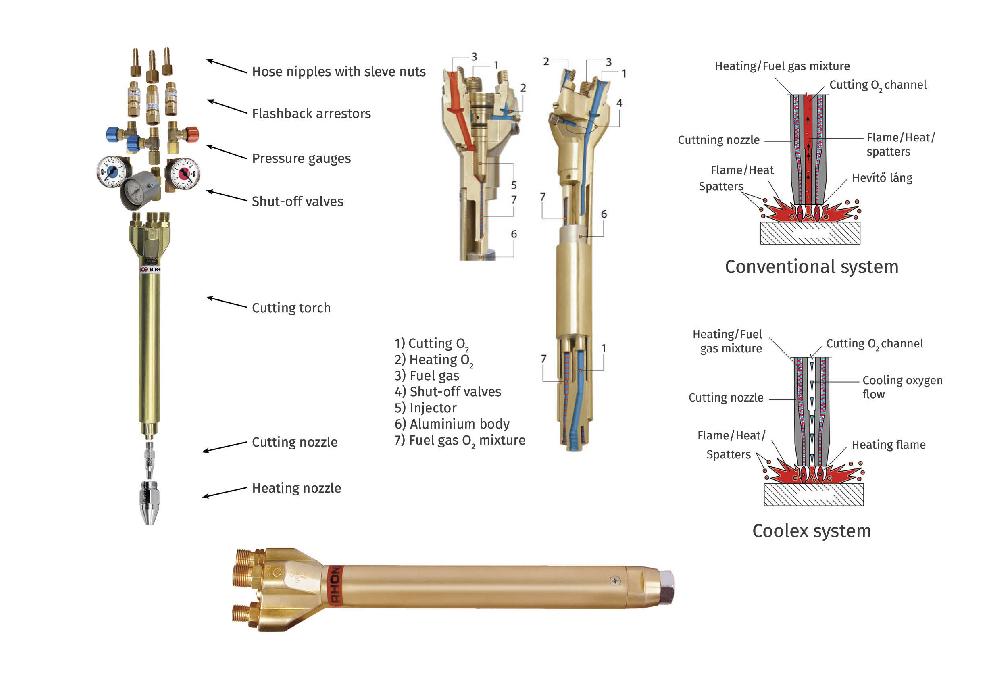

BIR+ Flame Cutting Torch

Integrated Coolex system

- The BIR+ contains a cool flow valve which provides a small amount of oxygen during preheating of the basic material. This small oxygen flow is streaming through the cutting oxygen channel to cool down the complete torch system and prevents the reverse flow of hot gases in to the cutting nozzle.

- The nozzle will be protected against early contamination.

- Longer nozzle life time

- Lower system temperature

- Constant shape of gas channels

- Constant gas flows

Safety Injector

A safety injector covered in a stable brass body is the basis for a safe function. Any overheating will be transported away from the injector which protects the torch against sustained backfire. Downstream of the injector an aluminium cooling unit completes the cooling function of the BIR torch which guarantees high operation safety. Sustained backfire hazard is minimized, also during extremely high load.

- High operation safety while hole piercing

- High service life of torch + nozzle

- High economy

- Less maintenance