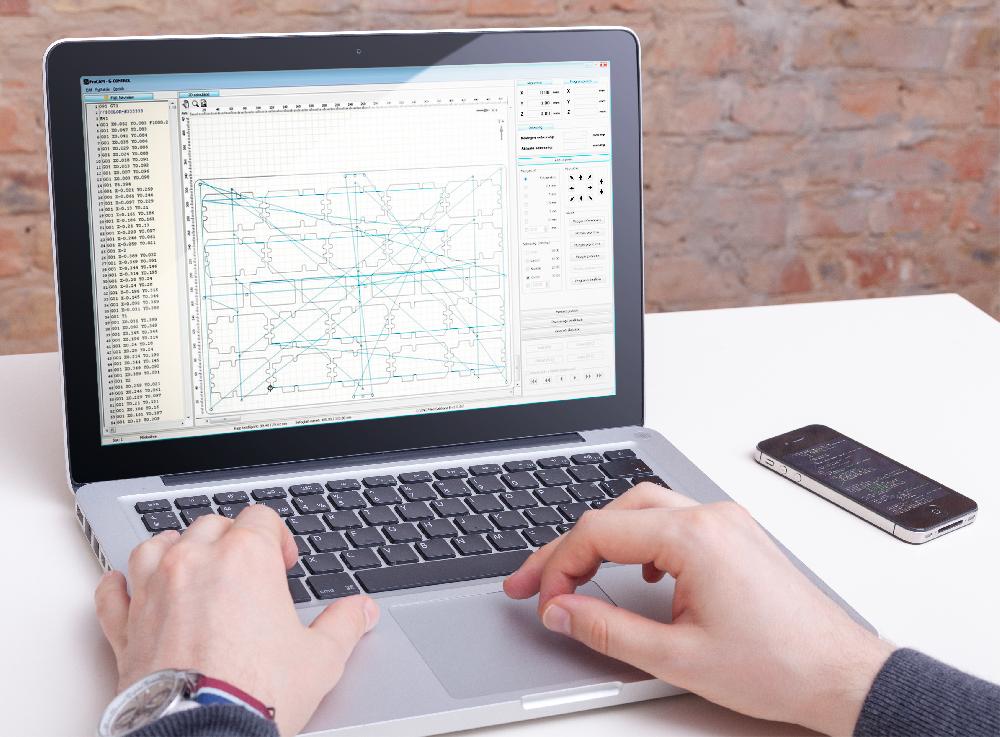

G-Control

One software for three technologies!

Our G-CONTROL software provides universal solution for the control of Waterjet, Plasma and Flame cutting systems-all in one software. A special advantage of the software and the controlling technology is that it is flexibly enhanceable/modifiable according to your specific demands.

Main features, advantages

Our software works as a Windows application, so it is a familiar and modern user-interface making it possible to run other softwares -like drawing and design softwares- in a parallel way. High precision, 3-axis control suitable for controlling servo and step motors alike. This is absolutely independent from the software so at later modifications you can use the same proven software. Direct DXF / PLT file importing option which you can use to upload the drawing created by your designer directly to the control software which also automatically converts it to G-CODE. This way you can use your existing tools.

Program operating option backwards without cutting. By this function you can step back to a previous condition correcting the occurring cutting faults. You can also jump to individual objects so the cutting can be continued from the starting point of any desired object. Gauge sensor control: by the pneumatic gauge sensor the software is able to automatically adjust the given cutting height. This function is essential for perfect cutting!

Full plasma cutting support: surface tracking, ignition and piercing delay, drill marking option, cutting stop before the end of the object. Plasma performance reduction at sharp turnings and before the end of the object with a set distance.

Full waterjet cutting support: piercing delay, abrasive control, delayed start-up and stop function. Besides that you can temporarily switch off the gauge sensor drastically reducing the cutting time for small objects..

Full flame cutting support: manual start, stop and pre-heating option.

By using the parameter table you can simplify the processing of the already used cutting materials. The pre-set data can be displayed by just one click again.

Quick and intelligent positioning option by setting the zero point at the centre of the object or any desired corner point. This function significantly simplifies the setting of the starting point of the cutting, accelerating the process.