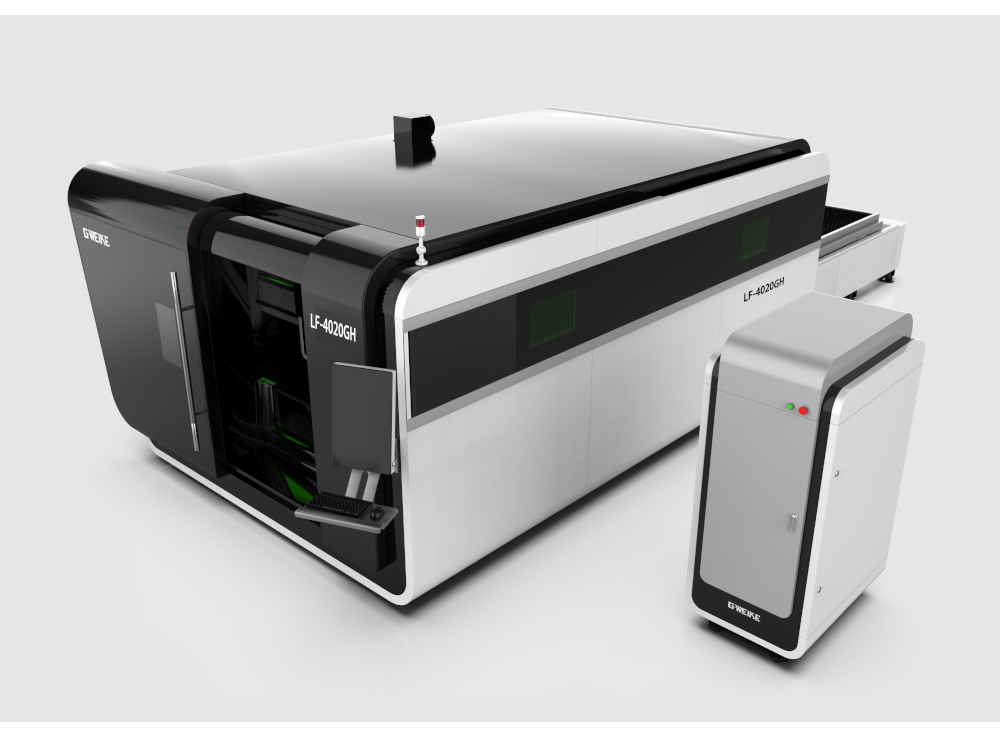

LF4020GH >> LF6025GH >> LF12025GH

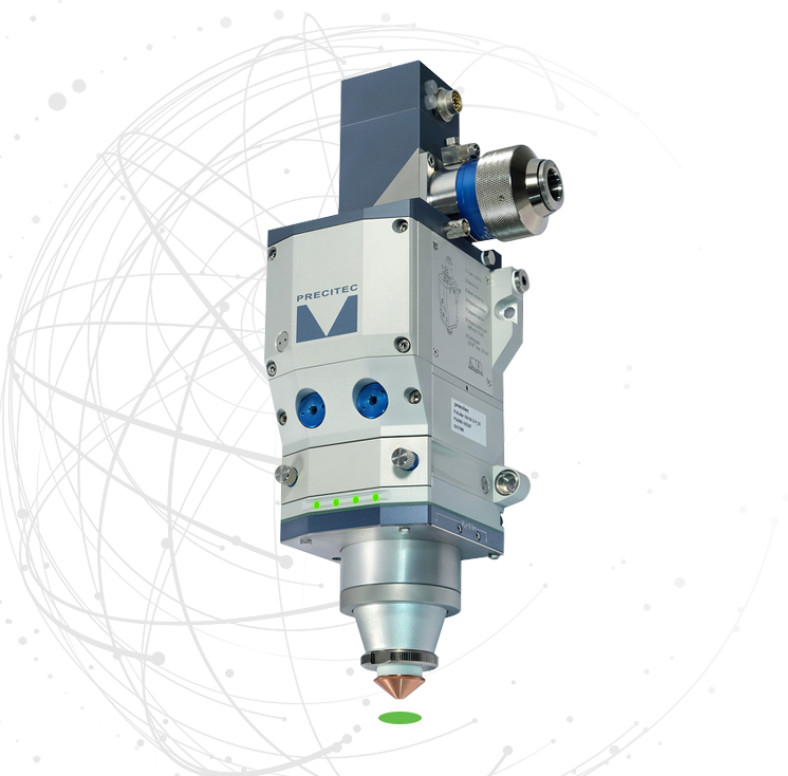

Auto Focus Laser Cutting Head

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Super heavy welded bed

It is welded by heavy steel plate, the current mainstream bed structure, high stability;

Effect force annealing treatment, high mechanical strength, not easy to deform;

Reinforcing ribs are arranged inside the bed to increase the strength and tensile resistance of the bed, and effectively avoid deformation of the bed;

The weight of the bed, the small vibration of the machine, and the good shock resistance ensure the improvement of cutting accuracy.

20000W IPG Fiber Lasers Source

World Famous Brand

GWEIKE laser cutting machine YLS-CUT series high power fiber laser of IPG. Powerful cutting ability with stainless steel, aluminum and other metal materials, cutting thickness is up to 40mm.

Long Service Life

The world leading IPG laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely.

Stable Cutting Performance

Fiber laser source can produce excellent beam quality, finer cutting lines, higher working efficiency and better machining quality. Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation.

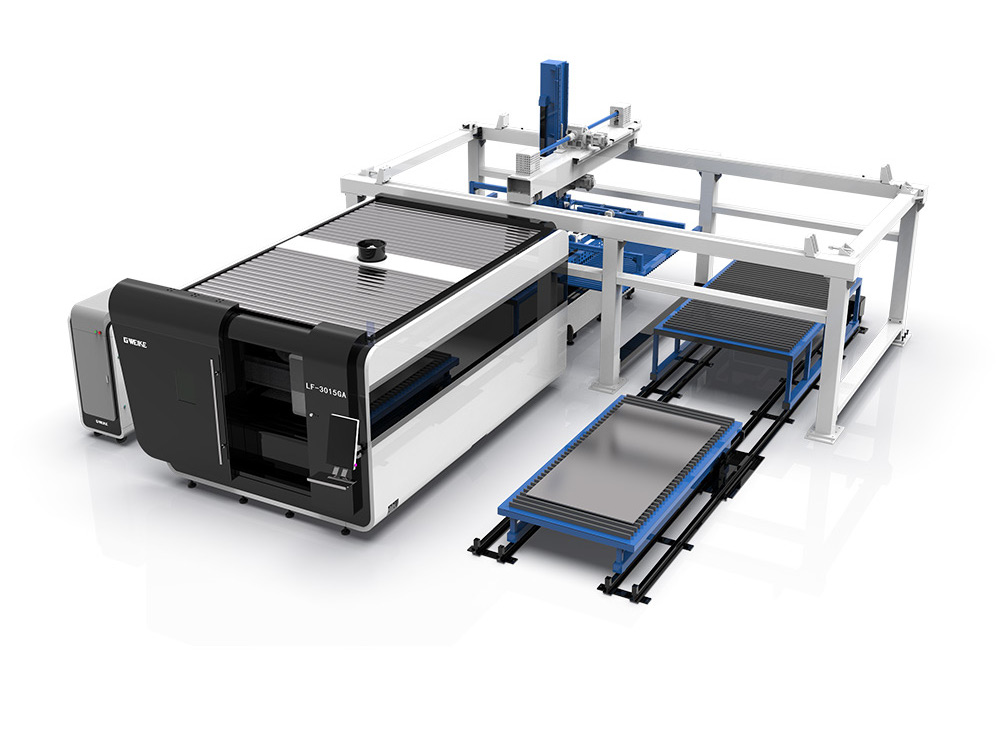

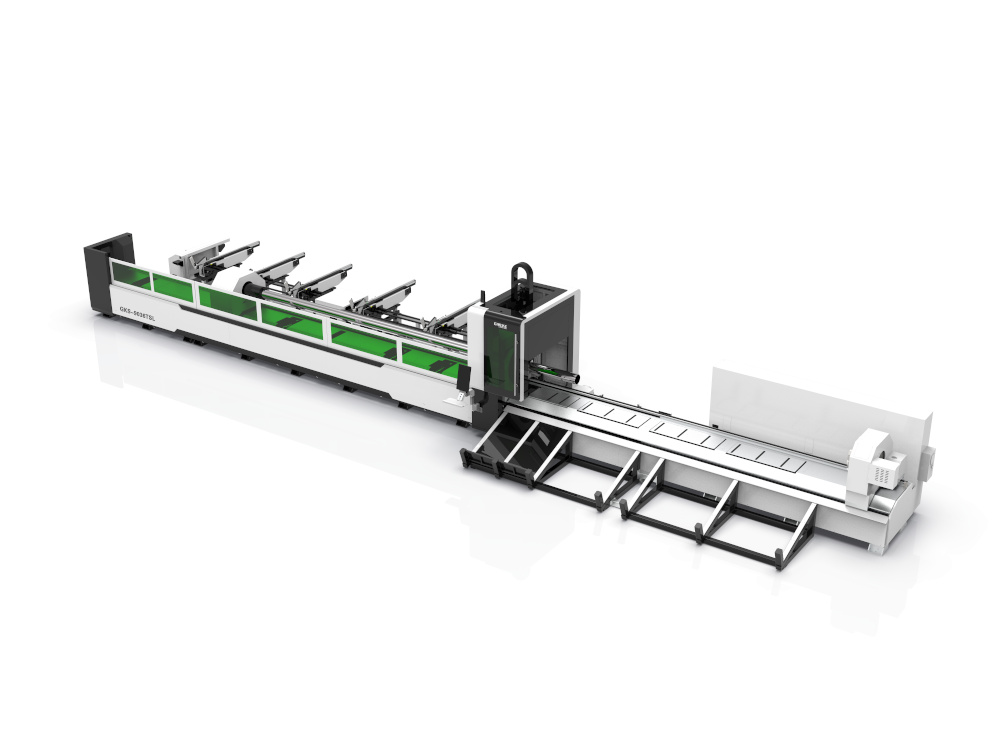

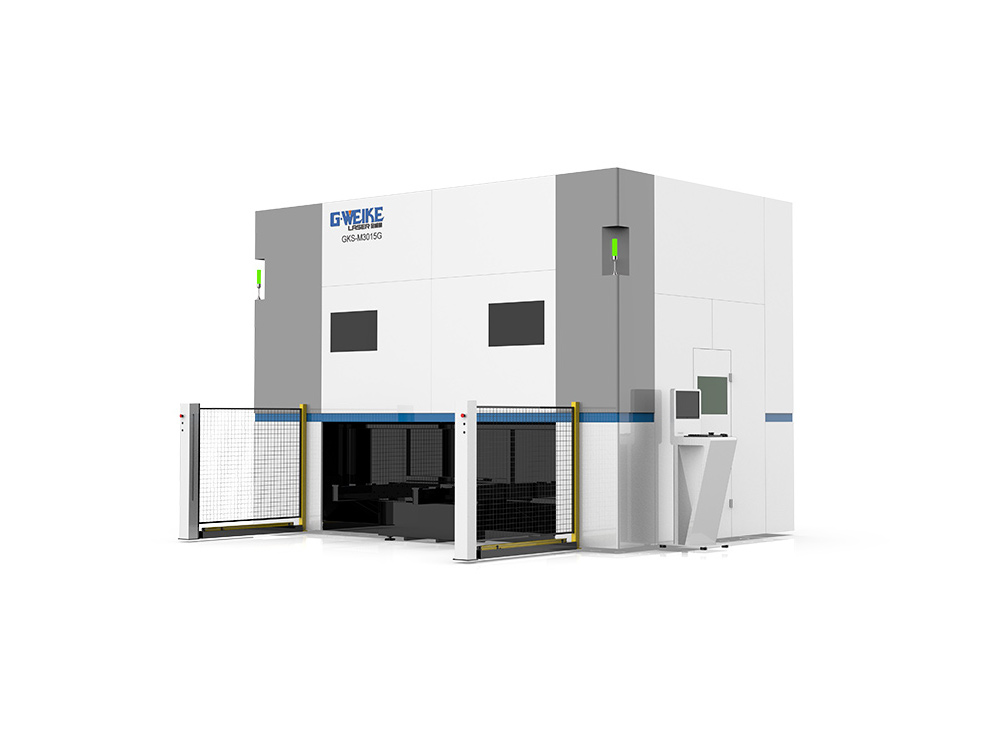

12M Full-page Thick Plate Cutting: Fast, Stable And High Quality

Gweike laser large format equipment includes 12025G (12m*2.5m), 10025G (10m*2.5m) The overweight bed process meets the diverse needs of the global market for large sheet metal cutting High-end, high-precision, high-speed, high-format and cost-effective.

PAD design display

Apple pad design, vertical screen display, wide viewing angle,

low power consumption, high resolution and high contrast.

The use of high-definition tempered glass, intelligent touch

control and fast response speed make the screen more

delicate and smooth, and the operation is smoother.

Segmented smoke exhaust-create a smokeless clean world

Full coverage, super suction

Adopt the latest cutting-edge tobacco control technology

Each section of the bed has a smoke exhaust device

Powerful negative pressure 360° adsorption

Axial fan wind direction surrounds blowing smoke downward

Full 360° strong adsorption and consistent smoke exhaust

Effectively purify the smoke and dust on the top of the enclosed cutting platform

Improve purification efficiency and reject lens contamination

Net follow-up, wisdom grows by quality

The smoke exhaust device automatically senses the laser cutting position

Turn on precise smoke exhaust, follow-up smart smokingCreate a concealed cavity, fully enclosed smoke control and clean smoke

Technical Parameters

| Machine model | LF4020GH | LF6025GH | LF10025GH | LF12025GH |

|---|---|---|---|---|

| Dimensions | 11475×2574×5169mm | 14937×3952×2287mm | 22953.5×4006×2336.5mm | 27092×4119×2336.5mm |

| Working area | 4000×2000 mm | 6000×2500 mm | 10000×2500 mm | 12000×2500 mm |

| Laser power | 8000W 12000W 15000W 20000W (Optional) | |||

| Repeat positioning accuracy | ± 0.02 mm | |||

| Voltage and frequency | 380V 50Hz/60Hz | |||

| Maximum speed | 200 m/min | |||

| Max. acceleration | 2.5 G | |||