Gweikecloud

Get Start In Less 30 Minutes

With AI vision algorithm, it can adjust to the pattern drawn on the material and automatically program the laser route without any other software! Just click the button to cut or carve! No need to manually adjust parameters.

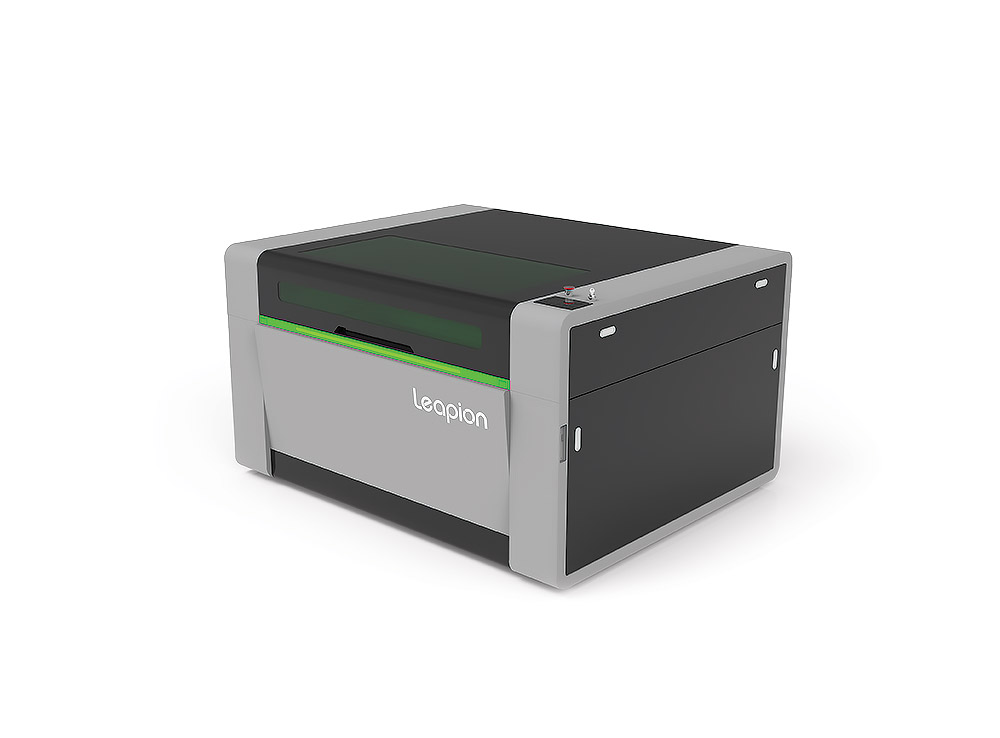

Industrial Grade Dust Filter

The machine is equipped with compact air filter, which can clean the dust produced during the process of running. You can use the machine at home, school and office as it is safe and pollution-free.

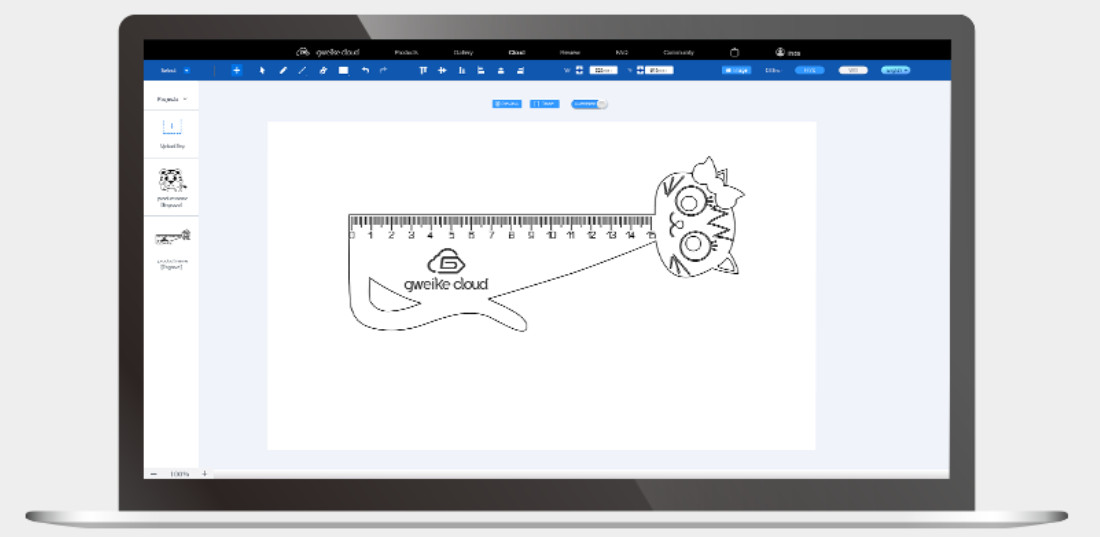

Cloud online Operation System

Your Gweikecloud runs from a web browser, which means there is no software to install - ever. Drag and drop your designs right onto your material. With AI vision algorithm, it can adjust to the pattern drawn on the material and automatically program the laser route.

The cloud service system can achieve real-time detection and remote operation of intelligent devices such as desktops, tablets and mobile phones. You can also view device faults, remote after-sales and other functions through mobile phones remotely.

CCD Scan Camera

Real-Time monitor, Smart Image Extraction With the AI computer vision algorithm, laser can automatically identify and extract the pattern of any object is surface. In collocation with the intelligent route planning system of Gweike cloud, it is easy to cut or carve out the pattern.

Super wide angle camera combined with image correction algorithm enables you to see the application effect of patterns on materials in real time. You can just drag and drop to adjust the size and position of the patterns to easily determine the working range of the laser.

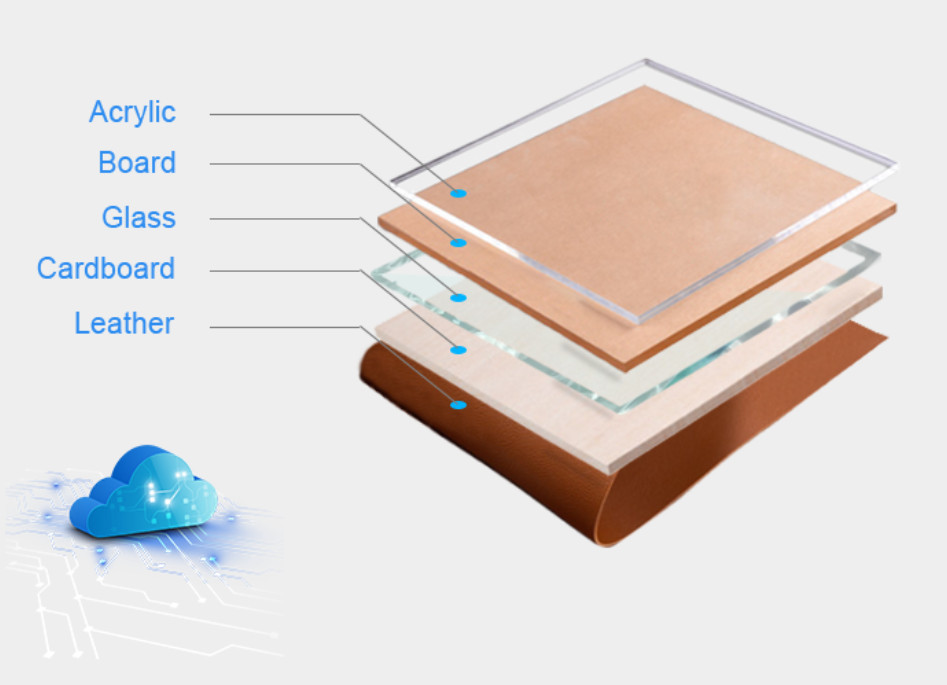

Identify Material Intelligently with AI Tech

Gweike Cloud can set parameters and memorize them automatically. By identifying the ring code on the material, Gweike Cloud can obtain the thickness and type of current material directly to automatically set the parameters for prime cutting or carving such as the prime focal length, speed, power, cutting times, etc. When stepping to the next operation, the users only need to put the cutting/carving patterns on the suitable position to achieve easy shuttle.

Technical Parameters

| Machine model | Home 3D Laser Cutter&Engrave |

|---|---|

| Laser power | 50W |

| Cameras | CCD scan camera |

| Processing Area | 20.08 (510 mm) * 11.8 (300 mm) |

| Machine Dimensions | 38.2 (970 mm) * 22.2 (565 mm) * 9.2 (234.5 mm) |

| Weight | 42.6 kg |

| Power Supply | AC 110-220V ± 10%, 50-60Hz |

| Resetting Positioning Accuracy | ±0,05 mm |

| Gross Power | 550W |