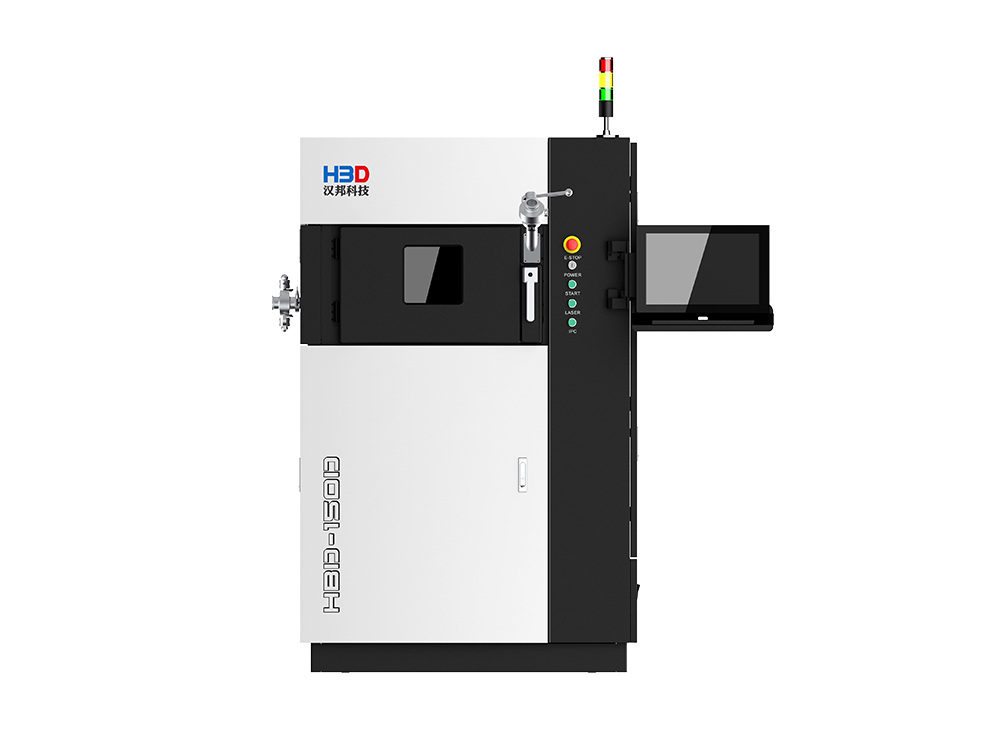

HBD-150D

Stability and Efficiency

HBD-150D adopts accurate and stable laser focusing system, with sub-vacuum-level sealed chamber, full closed-loop air volume control circulation purification system, high-speed deoxygenation system, combined with high-precision oxygen content detection, dual pressure sensor detection, dual gated safety control and detection, and active and passive dual pressure relief protection to ensure equipment safety, stability and efficient operation. HBD-150D supports the full base-plate printing with 235 units, normally printing 150 units needs 4 hours. Standard partial dentures printing efficiency is 12 to 17 pcs at 5 to 7 hours. It is equipped with innovative powder recycler to ensure high powder utilization rate.

Excellent Performance

HBD-150D is equipped with an external purification circulation system, which is in real-time communication with the host machine, real-time monitoring and responding the forming atmosphere. It is also equipped with fully automatic closed-loop purification circulation system, which is with pulse automatic full-scale rotation dust removal function; secondary filtration structure. With these configurations, the overall filtration efficiency may reach H13 standard. The total service life of the filter could be more than 2000 hours, and could meet the printing tasks of high-intensity, long-term and continuous production.

Security Upgradation

The model is equipped with a sealed glove structure, and a sealed tank for adding powder and powder suction, which is reserved for powder addition and powder cleaning operations without opening the chamber door, avoiding powder contact with air to the greatest extent and reducing the direct contact of the operator with powder, effectively ensuring the equipment safety when printing active metals such as titanium alloys.

Easy Operability

With the ergonomic design, a user-friendly device operation interface, intelligently realizes one-key start, one-key print function, minimizing the operation process, shortening operating time and lowering operation errors probability.

Material Diversity

Parameter packages of titanium alloy, cobalt chromium alloy and other materials will be provided. We offer open powder system and could cooperate to test the third party materials and provide the process parameters.

Data Processing Software

HBD-150D is deep customization with Magics Print Metal for HanBang, the dental data processing software of Materialise. The software realizes automatic laying out, automatic support adding, intelligent slicing and scanning path planning, which implements in-depth docking with equipment execution software, is automatic error correction, and simple operation.

Compatible CAD Software

HBD-150D is suitable for the most of CAD software, including 3Shape, Exocad, Dental Wings, etc.

Technical Parameters

| Laser System | Fiber Laser / 200 W |

| Forming Size | φ159 x 100 mm |

| Layer Thickness | 10-40 μm |

| Focus Diameter | 40-80 μm |

| Max Scanning Speed | 10 m/s |

| Typical Accuracy | 0.05-0.1 mm |

| Inert Gas | Nitrogen or Argon |

| Power Supply | 110/220 VAC, 50/60 Hz |

| Production Efficiency | Crown: 200-230 Units / 5-5.5H Partial Dentures: 12-17 PCS / 5-7H |

| Metal Powder | Co-Cr Alloy, Ti Alloy... |

| Machine Dimension | 1150 x 1150 x 1830 mm (L*W*H) |

| Machine Weight | 900 kg |

Dental Application

HBD-150D is used for manufacturing dental products such as crowns, bridges, implants, caps, bars, brackets, model casting and personalized customization,etc., with high density and perfect fit for patients.