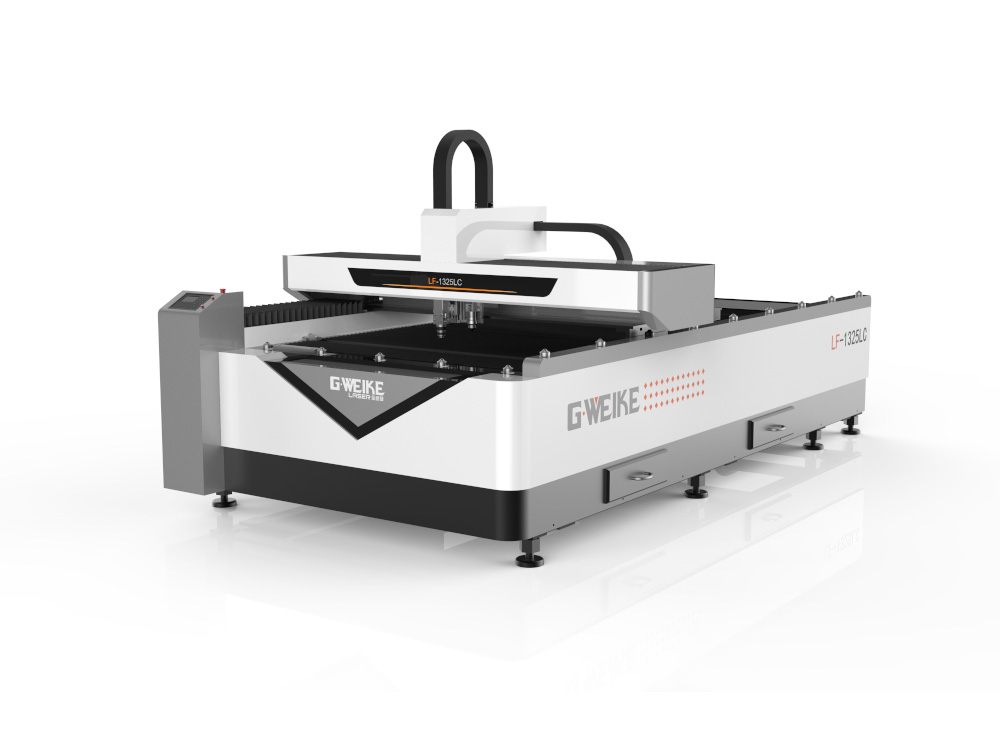

LF3015CN

Autofocus Laser Cutting Head

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

Independent Control Cabinet

Dust-proof

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolongthe lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature damage to components in summer.

The Segmented Rectangular Tube Welded Bed

Stress Relief and Heat Treatment

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

High strength, stability, tensile strength, ensuring 20 years of use without distortion; Thickness of rectangular pipe wall is 10mm and weights 4500 kg.

Technical Parameters

| Machine Model | LF3015CN | ||

|---|---|---|---|

| laser power | 1000W, 2000W, 3000W, 4000W (Optional) | ||

| Dimensions | 4600×2450×1700 mm / 7999×3048×1880mm | ||

| working area | 3000 x 1500 mm / 6000×2000 mm | ||

| Repeat positioning accuracy | ±0,02 mm/m | ||

| Max speed | 120 m/min | ||

| Max acceleration | 1,0 G | ||

| Voltage and frequency | 380V/50Hz/60Hz/60A | ||