LW Laser Welding Machine

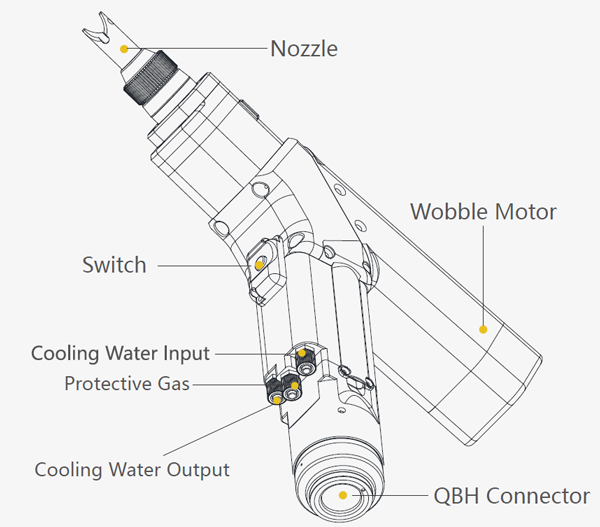

Smart high frequency swing welding head

Can be widely used in metal equipment, stainless steel home and other industries complex irregular welding process;Perfect replacement of traditional argon arc welding, electric welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials welding.

Clever interior design and good interactive control system expand the tolerance range and weld width of machined parts,solving the spot tiny disadvantage, and the weld formation is better.

Lightweight shape, body engineering design method, comfortable grip; One hand easy to control, easy to operate. With multiple security alarms, automatic light lock after moving parts, high security. Beautiful weld, fast speed, no consumables, no welding mark, no discoloration, no need to polish later. Can be configured with a variety of Angle nozzle to meet the welding needs of different products.

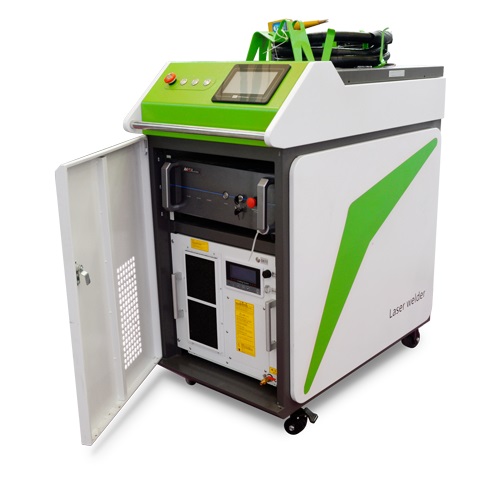

Break through the limitations of the workbench and save space costs

AThe machine is compact in design, and the LF-W-series is only 1/3 of the solid YAG laser welding equipment. Small body shape, free up more space, reduce the cost of equipment to occupy the plant space. Transmission fiber can be optional on demand 5/10/20 meters, up to the range of free-to-adjust.

Overcome traditional defects and save on maintenance costs

Continuous laser mode, compared to traditional welding equipment, welding transition smooth, no fish scales. Welding thermal influence area is small, the welding yellow-haired black area is small, the overall deformation of the workpiece is small, greatly improve the aesthetics of welding. LF-W series welding machine basically no supplies cost. Pump source life of up to 100,000 hours, daily basic maintenance-free.

TECHNICAL PARAMETERS

| Model No. | LW-500W | LW-1000W | LW-1500W | LW-2000W | |

|---|---|---|---|---|---|

| Operating Mode | Continous / Modulation | ||||

| Laser Wavelength | ±2% | ||||

| Power Requirements | 220 V | 220 V / 380 V | 220 V / 380 V | 220 V / 380 V | |

| Machine Power | ≤5 kW | ≤7 kW | ≤9 kW | ≤11 kW | |

| Operating Environment Temperature Range | 15-35 °C | ||||

| Working Environment Humidity Range | <70% No Condensation | ||||

| Welding Thickness Range | 0.5-0.8 mm | ||||

| Welding Line Requirements | ≤0,5 mm | ||||

| Welding Speed | 0-120 mm / s | ||||

| Machine Size | 1190 x 1100 x 650 mm | ||||