Streamline PRO2

With its PRO high-pressure range, KMT Waterjet Systems sets new standards in the field of water- jet cutting. Pro stands for waterjet cutting technology with operating pressures of up to 6,200 bar, and the new range of products of course includes all necessary components and accessories - from high-pressure generation units to orifies that guide the cutting jet with great precision onto the material.

- STREAMLINE PRO Ultra high-pressure pumps

- ACTIVE AUTOLINE PRO abrasive cutting head

- ACTIVE IDE PRO abrasive cutting head

- AQUALINE PRO pure water cutting head

- AMS PRO abrasive management system

- PSC PRO valves, pipes and fittings

Taking into account the increased exposure to high pressure, the PRO products were designed to ensure economical operation with enhanced service life. The original PRO series by KMT Waterjet thus offers you optimized high-pressure equipment meeting the highest requirements as regards reliability and cutting quality in heavy-duty continuous operation.

Advantages of Waterjet Cutting at 6,200 bar

Compared to conventional waterjet cutting at 4,100 bar, the increased maximum pressure range features the following benefits:

- Higher cutting speeds

- Improved cutting edge quality

- Lower abrasive consumption

- Higher productivity

- Optimized machine utilization

- Improved conformality

- Reduced delamination

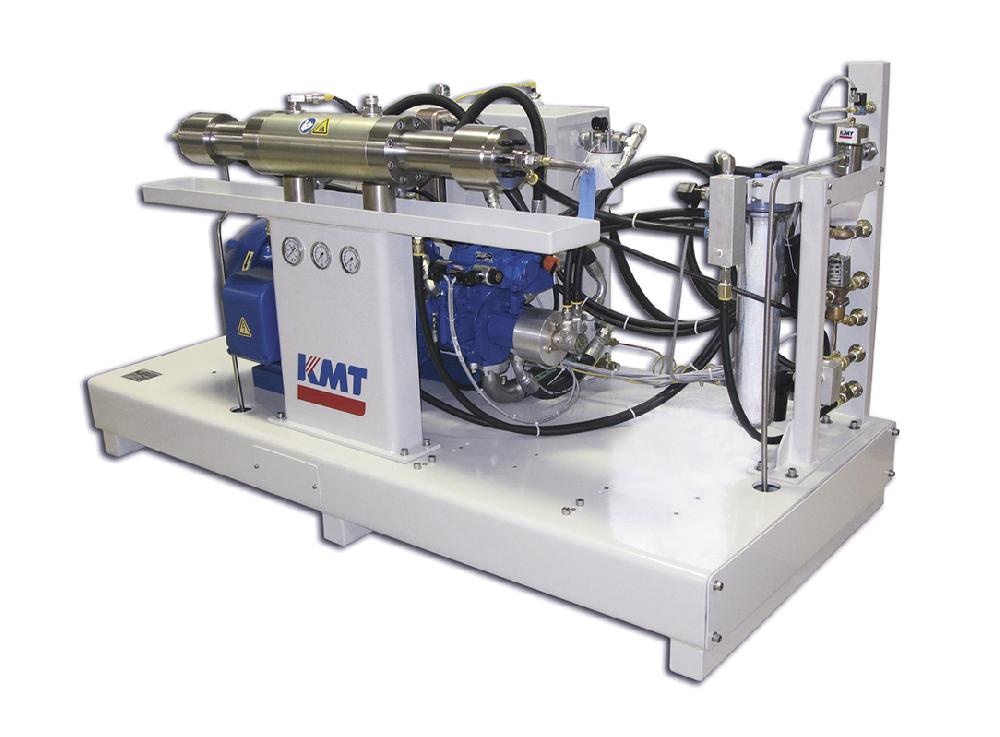

Ultra-high pressure pump STREAMLINE Pro

The high pressure pumps of the STREAMLINE™ PRO series have significantly enhanced the productivity and efficiency of the waterjet cutting technology. The innovative high pressure pumps have been designed for both pure water and abrasive waterjet cutting at operating pressures of up to 6,200 bar.

The STREAMLINE PRO is available in two models with 45 kW or 93 kW. At a pressure of 6,200 bar, the two machine versions offer volumetric flows of 2.7 l/min and 5.8 l/min respectively. This enables the operator to cut with either single or multiple heads.

Two pressure intensifiers for an optimized pressure signal

In the PRO 125 with 93 kW, the cutting pressure of 6,200 bar is produced with the help of two pressure intensifiers, which are operated with a phase shift. These intensifiers pump the cutting water through a 1.6 l pressure accumulator to the cutting heads. The standard model comes with a proportional pressure control system for the stepless adjustment of the cutting pressure. It is also equipped with a pressure transducer monitoring the cutting pressure in the high pressure line. This control circuit ensures equal utilization of the two pressure intensifiers and optimizes the pressure signal, which significantly affects the cut edge quality of the workpiece.

With the introduction of the 6,200 bar Pro technology, KMT Waterjet Systems set new standards in the field of waterjet cutting. With the launch of the next generation of this advanced technology, the StrEAMLinE Pro-2 uHP pump, KMT offers the industry’s most powerful combination of horsepower and pressure with significant advances in uptime.

High efficiency thanks to reduced maintenance

Due to the unique and simple design of the new Rapid Change INTENSIFIERSM and more durable components, the STREAMLINE PRO-2 intensifier requires substantially less time for replacement of parts than conventional waterjet pumps. As a result, preventive maintenance is kept to a minimum.

The STREAMLINE PRO-2 state-of-the-art intensifier quick seal change process means more uptime as seals can be replaced within 20 minutes only.

Reduced maintenance is also attributed to the longer reciprocal stroke rate to move more volume of water, which also extends the life of the seals. This improved reliability and flexible ergonomic design combine to provide extremely efficient cost savings and improved productivity.

What makes the maintenance even simpler is the fact that the STREAMLINE PRO-2 Rapid Change INTENSIFIERSM features only a comparably small amount of parts and components and that the necessity for specialty tools when changing seals is reduced considerably.

Benefits of KMT’s rapid Change UHP INTENSIFIERSM

- Maintenance friendly design = more uptime

- Reduces seal change time by 50% vs. conventional UHP pumps

- Low torque hard seal end cap design

- Eliminates complicated bolt tensioning and tie rods

- Reduces specialty tools required

- Longer lifetimes of seals and consumable parts

- Improved cylinder alignment

- Fewer component parts

Techinical paramteres

| PRO-2 125 | PRO-2 60 | ||

|---|---|---|---|

| Motor Rating | 93kw/125hp | 45kW/60hp | |

| Pressure Range | 800-6200 bar | ||

| Max. Flow Rate at max. Pressure | 5,8 l/min | 2,7 l/min | |

| Intensifier Design | Rapid Change | ||

| Label acc. to EC-Mach. Directive | CE mark | ||