Streamline SL-V plus

The STREAMLINE™ SL-V pumps enable you to use the generated pressure for both pure water and abrasive applications. Regardless of how your machine concept is designed: the STREAMLINE™ SL-V pumps can be installed and operated either independently or they can be controlled remotely through any kind of central control system.

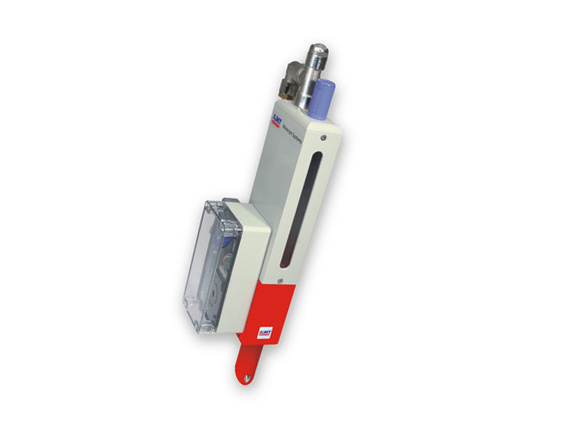

STREAMLINE SL-V 50/100 Plus

Designed for multiple shift operation

Day by day, hundreds of our STREAMLINE™ pumps do their job, often up to 3 shifts per day. In partic- ular, automotive end-users honor their outstanding high reliability level.

Working pressure of up to 4,136 bar

The pump units are available in two different power rates (37 and 74 kW). Wherever required, the STREAMLINE™ SL-V supplies high pressure water of up to 4.136 bar. In those areas where such a high pressure is not needed, the STREAMLINE™ SL-V can cut material at a lower pressure.

Booster pump protection

Sensors in front of and behind the booster pump assure that the flow of water is continual and adequate. This is an important feature to protect components particularly in the high pressure section.

Softstarter as standard saves electricity costs

The included softstarter additionally helps you to decrease your operating cost by reducing peaks in the consumption of electricity. Your local current supply usually does not have to get modified to install the STREAMLINE™ SL-V unit.

MOELLER touch Screen Control with multi-language display

The Moeller touch screen control system provides you with all comfort you can expect from a control system. You can select up to 11 different display languages. You have access to individual alarm histories to achieve best components lifetimes and you get guided very accurately through any maintenance related topic.

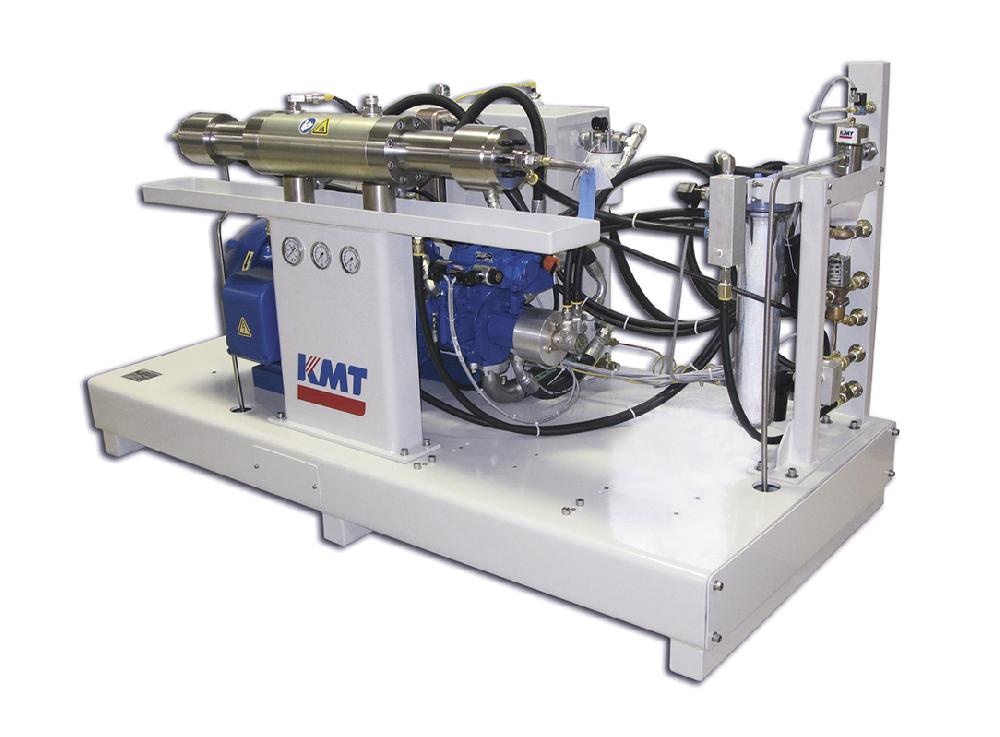

STREAMLINE SL-V 200 Plus

The model STREAMLINE SL-V 200 Plus by KMT WATERJET SYSTEMS is an advanced pump for large demanding high pressure waterjet applications. The high volume intensifiers are designed for ease-of-use, simple maintenance and low total costs.

High pressure water reliability

Some KMT high pressure pumps have the option to install an additional intensifi as standby. This means that there is a spare capacity in the volumetric fl w providing extra dependability for demanding production schedules.

Minimal floor space required

One 200 horsepower pump requires much less floor space than four 50 horsepower pumps. Moreover, the installation of just one single pump leads to reduced efforts in terms of installation material and external balancing equipment thus saving additional space.

Customer-focused design

The intensifiers are located in the front of the machine for easy access during physical inspections and maintenance. Removable swinging front doors additionally facilitate the maintenance procedures.

Reduced total costs

The costs of one pump (both operating cost and investment cost) are lower than those of several smaller pumps, and the minimized number of wear parts of just one pump further results in lower operating costs.

Intensifier capacity modes

Partial Operation Mode

In order to keep the production running even if one intensifier needs maintenance, the pump can run with one intensifier only. This feature provides 50 % uptime.

Reserve Mode (Option)

Add an optional third intensifier as a backup source of pressure. The third intensifier can be used when one (or two) of the others needs to be taken offline for maintenance. Each intensifier can use up to 100 hp.

| SL-V 100 | SL-V 50 | |

|---|---|---|

| Motor Rating | 74kw/100hp | 37kW/50hp |

| Pressure Range | 500-4136 bar | |

| Max. Flow Rate at max. Pressure | 7 l/min | 3,5 l/min |

| Intensifier Design | HSEC 23 | HSEC 20 |

| Label acc. to EC-Mach. Directive | CE mark | |