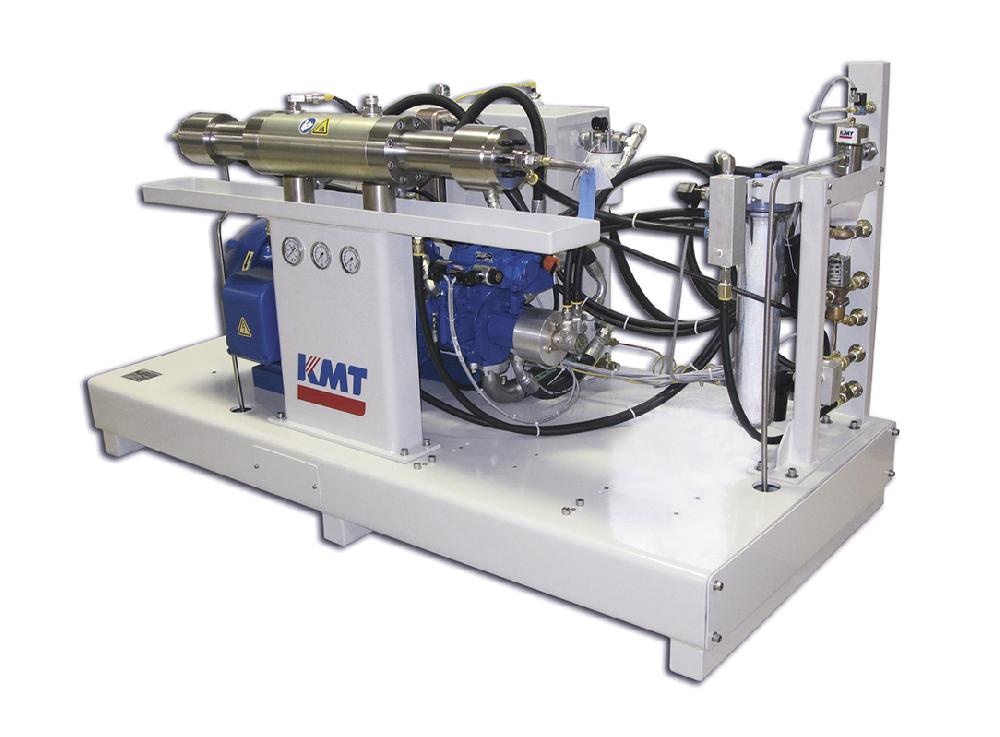

ECOTRON Intensifier

BFT, ONE OF THE WORLD‘S LEADING SUPPLIERS OF HIGH PRESSURE PUMP SYSTEMS, PRESENTS:

ECOTRON® & ECOTRON® +. THE HIGH PRESSURE PUMP DESIGN IS OPTIMIZED FOR MANUFACTURER OF WATERJET CUTTING SYSTEMS!

AHIGH PRESSURE PUMPS SERIES ECOTRON® & ECOTRON® + ARE CHARACTERIZED BY THE FOLLOWING FEATURES:

BASIC EQUIPMENT

The basic design of this high pressure pump includes a complete hydraulic drive unit with oil/water cooler, high pressure intensifier, accumulator and bleed down valve. The operating pressure is controlled by proportional valve and continuously adjustable via the touch panel between 50 and 400 MPa. All hydraulic and high pressure components are mounted on a base frame and covered by a sound insulated housing. The electric control is installed inside a switch box attached to the basic frame of the pump.

OPTIMIZED HYDRAULIC SYSTEM

The hydraulic unit is characterized by highly dynamic controls. Use of a soft-switching hydraulic valve with specially designed control geometry guarantees extremely short switch-over times. Oil filtering and cooling take place via the axial piston pump of the hydraulic drive. The excellent oil quality this achieves has a positive influence on operational safety and the life expectancy of the whole hydraulic system.

OIL COOLING

As a standard the pump is equipped with an oil/water cooler. It is installed on the base frame inside the pump housing. As an option an oil/water cooler is available. If the ambient temperature is lower than 35°C, an air cooler may be used. This eliminates the entire cooling water requirements. For higher temperatures the water cooler is available. Cooling water flow is controlled via thermostat.

FEED WATER SUPPLY

The feed water line is equipped with an on/off valve. If the pump is stopped there is no flow of water. The fitted pre-filtering unit with 5 μm and 1.2 μm filters guarantees optimum feed water supply. If the feed water pressure is lower than 0.3 MPa, an optional booster pump is available to increase the water pressure.

AT THE CORE - THE PRESSURE INTENSIFIER

The high pressure components in the intensifier are characterized by a long life expectancy. Besides the special stainless steels developed specifically for this application, a large plunger diameter and a long stroke both help to achieve this. Thanks to the special flange design and externally accessible check valves, the intensifier is easy to maintain. Wearing parts like seals and check valves can be replaced quickly and easily.

REDUCED PRESSURE FLUCTUATIONS

Depending on the flow rate of the pump, the integrated accumulator has a large volume of 0.88 or 1.6 litres. At the ECOTRON® it is even 2.49 litres. This reduces pressure fluctuations to a minimum and thus prevents wear on the high pressure system.

PRESSURE ADJUSTMENT

Electronic pressure adjustment via proportional valve is standard. At the operating panel two different operating pressures (e.g. piercing and cutting pressure) are adjustable. The switch-over between both pressures is done internally and externally via digital signal. The working pressure is adjustable at the operating panel directly at the pump or via external analogue signal from 0 to 10 V.

BLEED DOWN VALVE

This pressure release valve is installed within the high pressure line of the pump. The valve is activated via the stop button or the emergency stop circuit. In addition it can also be controlled externally, e.g. if needed for the piercing process with abrasive waterjet.

ELECTRIC CONTROL

The switch box is directly mounted at the base frame of the pump. Control is done via the integrated touch panel. Operating pressure of all ECOTRON® high pressure pumps is continuously adjustable between 50 and 400 MPa. All warnings and monitoring functions are displayed in clear text. Operating data are recorded and can be retrieved via the display.

REMOTE CONTROL SUPPORT

All important functions can be remotely controlled. External connectors are available for start/stop, emergency stop circuit, bleed down valve, malfunction and operating messages. Operating pressure setting is done via 0 to 10 V signal.

On request, multiple-voltage and multiple-frequency motors are available for ECOTRON® & ECOTRON® + series high pressure pumps.

System diagram for high pressure pump ECOTRON®

EECOTRON® & ECOTRON® + HIGH PRESSURE PUMPS

are built in compliance with Safety of Machinery Directive 98/37/EG and the Pressure Equipment Directive 97/23/EG. Depending on the type of used components there are installation instructions or a declaration of conformity with CE mark included in the documentation.

Correlation between operating pressure, flow rate and orifice diameter.

ADVANTAGES OF ECOTRON® +

- Large accumulator with 2.49 litres and an oil/water heat exchanger are standard on the +- Version.

- The control of the ECOTRON® + allow the connection of a Profinet card. With this, the pump is ready for Industry 4.0.

- The boosterpump and a safety valve provide a constant pressure at the inlet of the intensifier.

- The central connection plate on the ECOTRON® + simplifies the installation on site.

- The gas damper on the hood of the ECOTRON® + keeps the noise protection cover in its position. This increases the safety and the stability of the cover.

| Technical Data | ECOTRON® | 40.11 | 40.15 | 40.19 | 40.22 | 40.30 | 40.37 | 40.37+ | 40.45+ |

|---|---|---|---|---|---|---|---|---|---|

| Power supply, main motor | kW | 11.0 | 15.0 | 18.5 | 22.0 | 30.0 | 37.0 | 37.0 | 45.0 |

| Auxiliary unit, oil/air cooler | kW | 0.28 | 0.28 | 0.28 | 0.28 | 0.28 | 0.28 | 0.28 | 0.28 |

| Auxiliary unit, booster pump | kW | 0.57 | 0.57 | 0.57 | 0.57 | 0.57 | 0.57 | 0.57 | 0.57 |

| Flow rate, max. | l/min | 1.2 | 1.5 | 1.9 | 2.3 | 3.1 | 3.8 | 3.8 | 4.3 |

| Design pressure | MPa | 420 | 420 | 420 | 420 | 420 | 420 | 420 | 420 |

| Permissible operating pressure, max. | MPa | 350 | 350 | 400 | 400 | 400 | 400 | 400 | 400 |

| Double strokes, max. | min-1 | 20 | 11 | 17 | 30 | 35 | 38 | 38 | 40 |

| Intensification ratio | 1:21,78 | 1:21,78 | 1:21,78 | 1:21,78 | 1:21,78 | 1:21,78 | 1:21,78 | 1:21,78 | |

| Accumulator, volume | l | 0.88 | 0.88 | 1.60 | 1.60 | 1.60 | 1.60 | 2.49 | 2.49 |

| Oil tank volume | l | 130 | 130 | 130 | 130 | 130 | 130 | 130 | 130 |

| Ambient temperature with oil/air cooler | °C | 10-35 | 10-35 | 10-35 | 10-35 | 10-35 | 10-35 | 10-35 | 10-35 |

| Air flow with oil/air cooler | kg/s | 0.83 | 0.83 | 0.83 | 0.83 | 0.83 | 0.83 | 0.83 | 0.83 |

| Ambient temperature with oil/water cooler | °C | 10-45 | 10-45 | 10-45 | 10-45 | 10-45 | 10-45 | 10-45 | 10-45 |

| Water consumption with oil/water cooler, ca. | l/min | 2 | 3 | 5 | 6 | 8 | 10 | 10 | 12 |

| Supply Lines | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Water inlet | 1/2“ | 1/2“ | 1/2“ | 1/2“ | 1/2“ | 1/2“ | 1/2“ | 1/2“ | |

| Water pre-pressure with booster pump, min./max. | MPa | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 |

| Drainage connection | 3/8“ | 3/8“ | 3/8“ | 3/8“ | 3/8“ | 3/8“ | 3/8“ | 3/8“ | |

| High pressure connection for HP tubes 3/8“ and 9/16“ | M20x1.5 | M20x1.5 | M20x1.5 | M20x1.5 | M20x1.5 | M20x1.5 | M20x1.5 | M20x1.5 | |

| Pneumatic pressure, min./max. | MPa | 0.55-0.70 | 0.55-0.70 | 0.55-0.70 | 0.55-0.70 | 0.55-0.70 | 0.55-0.70 | 0.55-0.70 | 0.55-0.70 |

| Pneumatic connection for hose (O.D.) | mm | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Supply voltage | V | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Frequency | Hz | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Current back-up fuse (400 V/50 Hz) | A | 32 | 32 | 63 | 63 | 63 | 80 | 80 | 100 |

| Protection type, control box | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | |

| Protection type, all other components | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Miscellaneous | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Width | mm | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Depth | mm | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Hight | mm | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 |

| Total weight (with auxiliaries) | kg | 760 | 775 | 810 | 830 | 900 | 1000 | 1050 | 1100 |

| Sound level, max. | dB(A) | ≤76 | ≤77 | ≤78 | ≤78 | ≤79 | ≤79 | ≤79 | ≤82 |

| Coating | Housing RAL 7036 Platin grey / Electric RAL 7035 light grey | ||||||||

Subject to technical alterations

| ECOTRON® | ECOTRON®+ | |

|---|---|---|

| Boosterpump for fresh water | ■ | ■ |

| Oil-Air-cooler on demand included | O | ■ |

| Central connection plate for water, air and drain | – | ■ |

| Gas damper on cover | – | ■ |

| Electronic soft start to avoid peaks | O | O |

| Temperature sensors on the valves to make preventive maintenance possible | O | O |

| Volume of Accumulator (litres) | 1.60 | 2.49 |

O Option

■ Standard

– Not available