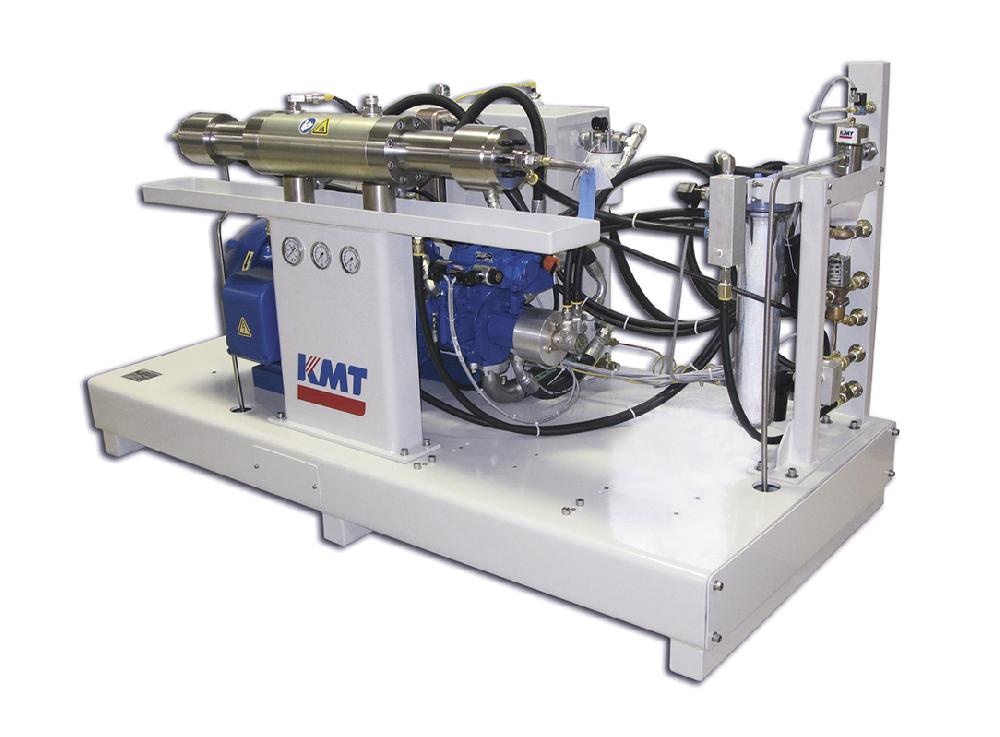

SERVOTRON Intensifier

BFT, ONE OF THE WORLD‘S LEADING SUPPLIERS OF HIGH PRESSURE PUMP SYSTEMS, PRESENTS

SERVOTRON®. THIS PUMP OPENS A NEW DIMENSION FOR YOUR WATERJET APPLICATIONS!

SERVOTRON® HIGH PRESSURE PUMPS ARE CHARACTERIZED BY THE FOLLOWING FEATURES:

THE BASE

Generally in mechanical engineering the term “servo” refers to a mechanism the purpose of which is to convert a small effort into a large effect with the aid of external energy. In electrical engineering a “servo” is considered to be a combination of a control and a drive unit. This knowledge is transferred to our high pressure pump series SERVOTRON® and due to this an environmentally friendly and energy efficient unit has been created.

DYNAMIC CONTROLS AND ENEGY EFFICIENCY

With the new SERVOTRON® type high pressure pump, this principle has been inverted. A gear pump with a constant flow rate is connected with a highly dynamic, frequency-controlled servo drive. In approximately 60 milliseconds, the motor is accelerated from zero to up to 2,700 rpm. This drive concept has a decisive advantage, i.e. improved energy efficiency! In comparison with asynchronous motors, the efficiency of this new drive concept with a frequencycontrolled servo drive is approximately 15% higher.

OIL FILTERING AND COOLING

The hydraulic oil is cooled by either an oil/air or an oil/water heat exchanger. Oil filtering and cooling take place in a separate and constant oil circuit. The excellent oil quality this achieves has a positive influence on operational safety and the life expectancy of the whole hydraulic system. In case of higher ambient temperatures a dual cooler with serial combined oil/air and oil/water cooler is available as option.

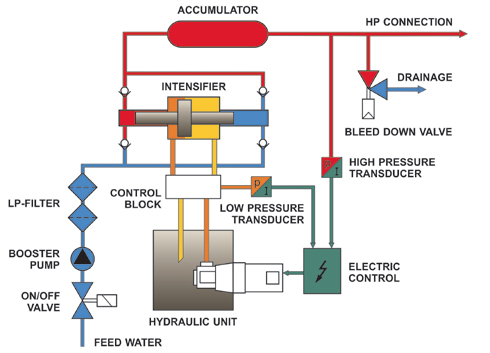

OPTIMUM FEED WATER SUPPLY

The installed booster pump, together with double filter unit with 5 μm and 1,2 μm, guarantees optimum feed water supply for the high pressure pump.

THE INTENSIFIER - THE CORE PIECE

The patended high pressure sealings and check valves in the intensifier are characterized by a long life expectancy. Besides the special stainless steels developed specifically for this application, the shrinked high pressure cylinder help to achieve this. In the DUAL CORE® technology two cylinders are shrinked into each another and the inner cylinder is autofrettaged in addition. For the multi-shift use of the pump, a stand-by intensifier is available as option.

SIMPLE MAINTENANCE

Thanks to the special flange design and externally accessible check valves, the intensifier is easy to maintain. Wearing parts like high pressure seals and check valves can be replaced quickly and easily.

LONG LIFE EXPECTANCY AND HIGH OPERATING SAFETY

The pump is equipped with a large volume accumulator. Due to the combination of highly dynamic servo drive unit and an accumulator volume of 2.5 liters, the pressure fluctuation in the high pressure system is +/- 1% only. This protects the whole high pressure system, prolongs the life time of high pressure sealings and check valves and also has a positive effect on the cutting result.

OPTIMIZED PRESSURE PROFILE

When switching the cutting valve on and off there is practically no pressure overload. The integral pressure transducer measures the actual operating pressure value so that if necessary it can be immediately adjusted. This means a significant reduction of pressure fluctuations within the pump and simultaneously a longer service life for all the high pressure components located between the high pressure pump and the cutting head.

BLEED DOWN VALVE IN HIGH PRESSURE LINE

A bleed down valve is fitted to the pump‘s high pressure line. The valve is pneumatically controlled and actuated via the stop button or the emergency stop circuit. It can also be controlled externally; this means you can set the pressure as needed, e.g. for the piercing process with abrasive waterjet.

TOUCH SCREEN CONTROLS

The pump is touch screen controlled. The operating pressure of SERVOTRON® high pressure pump is continuously adjustable between 10 and 400 MPa. All warnings and monitoring functions are displayed in clear text. Operating data are logged and can be accessed via the display. In addition, the pump has a diagnostic system and an electronic log book. Data and operating life of the individual components can be read via an USB port.

REMOTE CONTROL SUPPORT

All important functions can be remotely controlled via client access. External connectors are available for start/stop, emergency stop circuit, bleed down valve, malfunction and operating messages. Operating pressure setting is done via 0 to 10 V signal.

On request, multiple-voltage and multiple-frequency motors are available for SERVOTRON® series high pressure pumps.

MORE THAN 24 % ENERGY SAVINGS!

SERVOTRON® HIGH PRESURE PUMPS

are built in compliance with Safety of Machinery Directive 98/37/EG and the Pressure Equipment Directive 97/23/EG. The declaration of conformity is included with the documentation.

System diagram for high pressure pump SERVOTRON®

- Highly dynamic, frequency-controlled hydraulic unit with servo drive and internal gear pump, dual version for higher flow rate.

- Excellent accessibility, easy to maintain and optimum operation.

- Feed water supply with booster pump and double filter unit.

- Control box with electric components and frequency controller.

| Technical Data | SERVOTRON® | 40.37 | 40.45+ |

|---|---|---|---|

| Power supply, main motor | kW | 37.0 | 45.0 |

| Auxiliary unit, oil/air cooler | kW | 1.1 | 1.1 |

| Auxiliary unit, booster pump | kW | 0.46 | 0.46 |

| Flow rate. max. | l/min | 3.8 | 4.6 |

| TDesign pressure | MPa | 420 | 420 |

| Permissible operating pressure. max. | MPa | 400 | 400 |

| Double strokes, max. | min-1 | 35 | 40 |

| Intensification ratio | 1:21.78 | 1:21.78 | |

| Accumulator, volume | l | 2.49 | 2.49 |

| Oil tank volume | l | 95 | 95 |

| Ambient temperature with oil/air cooler | °C | 10-35 | 10-35 |

| Ambient temperature with oil/water cooler | °C | 10-45 | 10-45 |

| Average water consumption with oil/water cooler | l/min | 9.0 | 10.0 |

| Supply lines | |||

|---|---|---|---|

| Water inlet | 1/2" | 1/2" | |

| Water pre-pressure, min./max. | MPa | 1.0-2.5 | 0.1-2.5 |

| Drainage connector | 3/8" | 3/8" | |

| High pressure connector for HP tubes 3/8“ | M20x1.5 | M20x1.5 | |

| Pneumatic pressure, min./max. | MPa | 0.55-0.70 | 0.55-0.70 |

| Pneumatic connection for hose | 3/8" | 3/8" | |

| Supply voltage | V | 400 | 400 |

| Frequency | Hz | 50 | 50 |

| Current, back-up fuse (400V/50 Hz) | A | 80.0 | 100.0 |

| Protection type, control box | IP55 | IP55 | |

| Protection type, all other components | IP54 | IP54 |

| Miscellaneous | |||

|---|---|---|---|

| Width | mm | 1950 | 1950 |

| Depth | mm | 970 | 970 |

| Height | mm | 1400 | 1400 |

| Total weight (without auxiliaries) | kg | 960 | 970 |

| Sound level, max | dB(A) | <78 | <78 |

| Coating | silver/gray | ||

Subject to technical alterations.

THE ADVANTAGES OF SERVOTRON® HIGH PRESSURE PUMP AT A GLANCE:

TOUR PERFORMANCE / YOUR BENEFIT

• Driven by highly dynamic, frequency-controlled servo drive

More than 24 % energy savings – certified by TUV

• Reduced operating temperature in the oil circuit

Less cooling power required, extended life time of hydraulic components

• Soft starter for starting the high pressure pump

Reduced current consumption during starting of pump

• Continuous pressure adjustment from 10 to 400 MPa

Increased range of application for the complete cutting unit

• Practically no pulsation at piercing

No damage at brittle materials, starting at 10 MPa

• Minimal pressure fluctuation, not more than +/- 1 % at full load

Increased life time of high pressure components and improved cutting quality

• No pressure overload and minimal pressure drop at on/off mode of cutting head

Prevents the complete high pressure system, from the pump to the cutting head

• At closed cutting head, no current consumption at servo drive

Reduced current consumption and increased energy efficiency

• Logbook integrated in control

Simplified handling, export of operating data via USB port

• Client connection via network cable

Take over of pump control into the control of cutting system