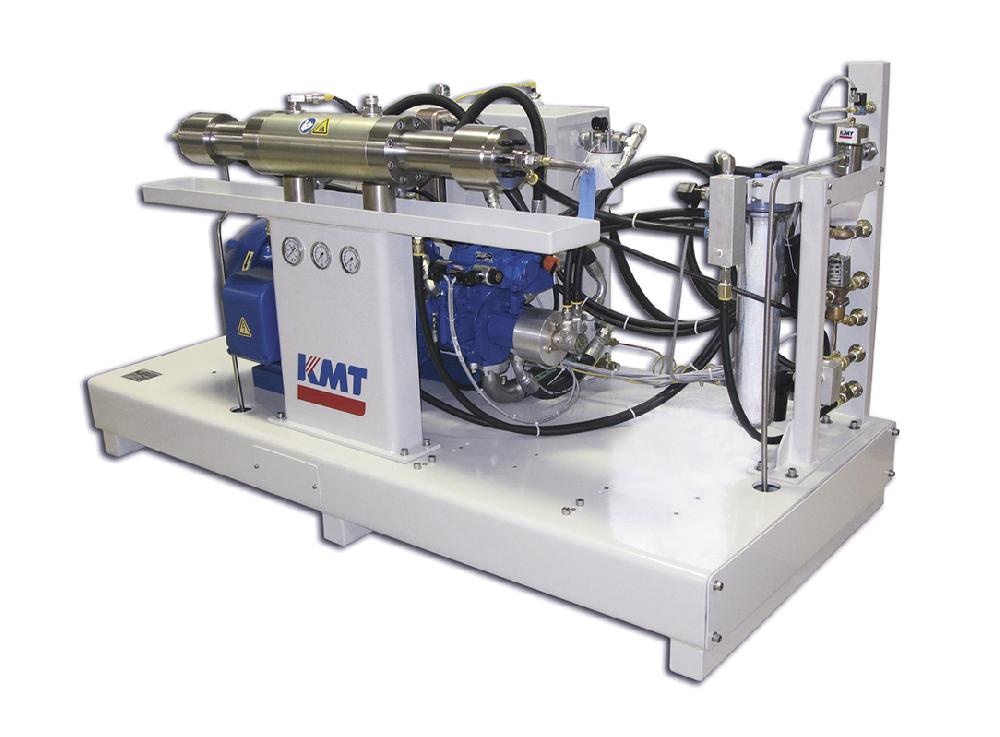

Active Autoline PRO / IDE PRO

The Pro abrasive cutting heads from KMT WATERJET SYSTEMS have been specially designed for waterjet cutting with 6,200 bar. Their design and materials can withstand huge forces while focusing the energy to the point where it is needed, namely to the cutting jet.

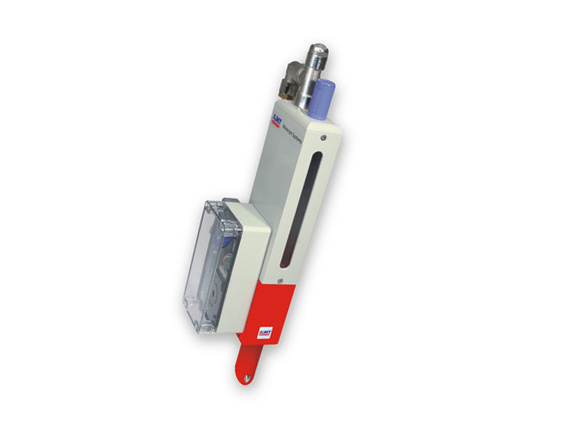

ACTIVE AUTOLINE™ Pro Abrasive cutting head

Among the outstanding features of ACTIVE AUTOLINE™ PRO cutting heads are automatic precision positioning, perfect repetition accuracy, high cutting speeds, long service life and easy maintenance. It takes only seconds to replace the few wear parts of the head, such as the orifice, mixing chamber and focusing tube, and no tools are required. In order to keep routine maintenance to a minimum, these parts are made from tough wear-proof materials. The typical features of KMT products based on the innovative approach for efficiency and economy in continuous operation have thus been successfully integrated into the design of the cutting head.

ACTIVE AUTOLINE™ PRO cutting heads can be integrated into all waterjet cutting systems with rigid or multiple head connections.

ACTIVE IDE™ Pro Improved cutting performance thanks to high precision

The ACTIVE IDETM PRO cutting head features a diamond orifice which is firmly integrated into the orifice body. A specially devised manufacturing method ensures that the waterjet is properly aligned at all times and connected to the mixing chamber located below the orifice body. In the mixing chamber, the abrasive is added to the waterjet. The stringent production tolerances for the mounted cutting head guarantee that the cutting jet is always properly aligned along the axis. As the waterjet exits the focusing tube at the correct angle, the power of the waterjet is focused for optimum impact. This allows for maximum cutting speeds at minimum cutting gaps combined with excellent cutting edge quality.

HYPERTUBE Pro focusing tube for 6,200 bar applications

With the HYPERTUBE PRO, KMT Waterjet has developed a patented design that considerably prolongs the service life of the focusing tube. In most cases, the focusing tube shows asymmetric wear, which results in an elliptic deformation of the outlet opening. HYPERTUBE PRO focusing tubes are equipped with an index that enables operators to repeatedly turn the tube by a set angle in the housing of the cutting head. This results in a uniform wear pattern so that the waterjet cross-section remains circular.

The jet remains properly focused for a longer period of time, which further helps reduce the operating costs of the waterjet cutting unit. Experience shows that this patented solution prolongs the service life of focusing tubes by around 100%.