Aqualine I / PRO

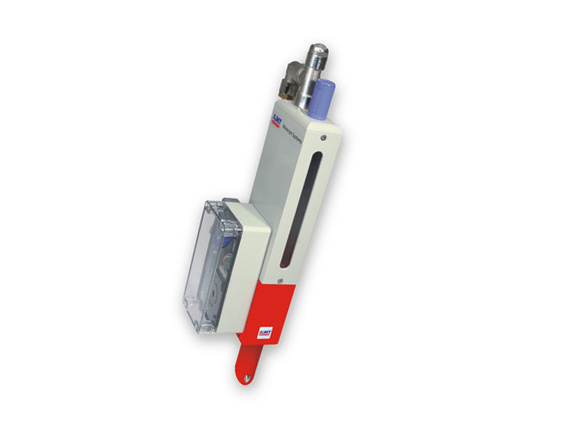

AQUALINE I

Especially automotive applications are among the most demanding of subcontracting jobs in the industry. Demands put on waterjet components are certainly not an exception, but a confirmation of this rule. Production units usually run 3x8-hour shifts throughout the complete week highlighting a need for extremely high reliability and speed.

Reliability under extreme conditions

Our AQUALINE I pure water cutting head has gained an industry-wide reputation for being amongst the quickest and the most reliable pure water cutting heads under extreme working conditions, through fastest reaction times and high component lifetimes and quality.

High performance nozzle valve

The multiple cutting cycles found in these industries place huge requirements on the on/off cycle speed and reliability of the cutting valve. The KMT AQUALINE I provides the industry‘s top quality leading solution in this area. Depending on the application, normally closed (N/C) and normally open (N/O) cutting valves are available. The nozzle valve opens in less than 50 ms depending on the operating pressure.

Compact design for flexible use

The AQUALINE I head weighs only 1.8 kg (3.9 lbs) guaranteeing high flexibility and making multi-head and 3-D applications easy. It can be equipped with both sapphire and diamond orifices, whatever fits the individual process needs best.

Pre-filter protects the water nozzle

The pre-filter is installed between the HD line and the nozzle valve body in the adapter. This component reduces the mechanical impact on the water nozzle, as particles are removed from the cutting jet so that they do not cause abrasion to the nozzle. This significantly prolongs the service life of the nozzle and lowers the operating costs.

| AQUALINE I | |

|---|---|

| Length | 91 mm |

| Width | 91 mm |

| Height (with 8” nozzle tube) | 448 mm |

| Weight | 1,8 kg |

| HP connection | 3/8” UNF |

| Mounting Screws (2x) | 1/4” x 7/8” |

AQUALINE PRO

The nozzle valve for maximum stress

The wide range of cutting tasks and numerous switching cycles puts a heavy strain on the nozzle valve. With the AQUALINE PRO pure water cutting head, KMT has developed the perfect solution for 6,200 bar applications. As the cutting speed is higher than with 4,000 bar, delamination is significantly reduced and in many cases completely eliminated. Depending on the actual requirements, the valves are available as normally open (N/O) or usually closed (N/C) valves. These high-pressure valves usually open in less than 50 ms, depending on the operating pressure. High precision, sturdy design and extremely short switching times are the key features of the AQUALINE PRO waterjet cutting head range.

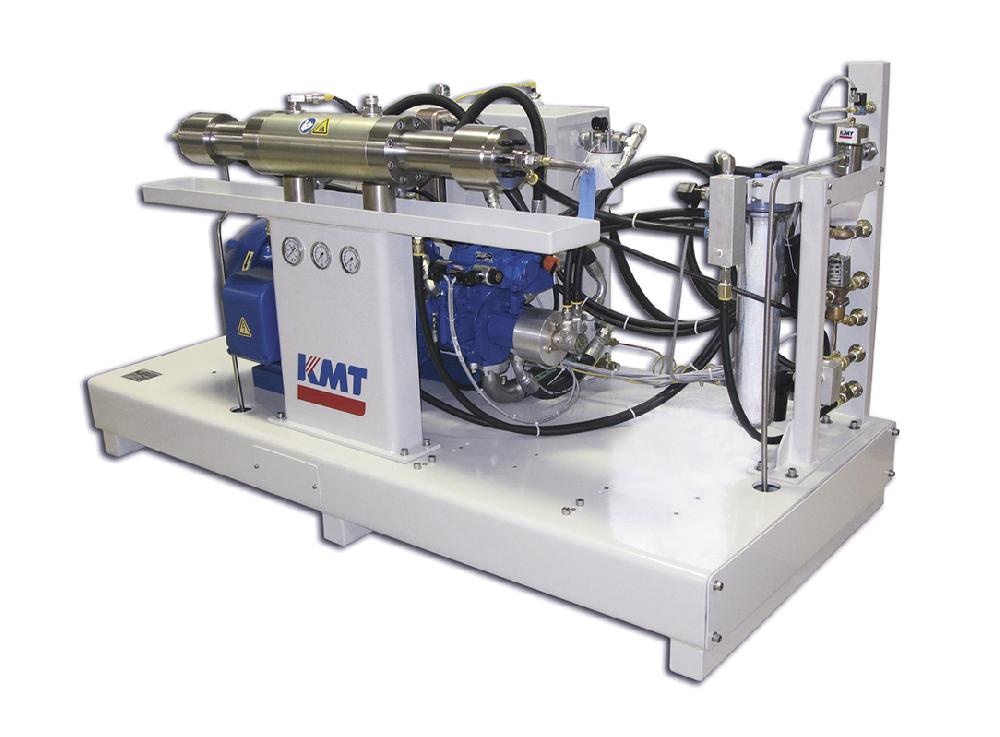

PSC-PRO 6,200 bar valves, connectors and pipes

PSC stands for Precision System Components, which include all installation parts required in high pressure cutting technology to feed the cutting water from the pump to the connected cutting stations. The PRO series of PSCs has been specially developed to meet the requirements of waterjet cutting with 6,200 bar. The comprehensive PSC-PRO range of products allows for the flexible and reliable installation of pipeline systems suitable for all commonly used cutting systems. PSCs from KMT offer unrivalled reliability, availability and wear-resistance