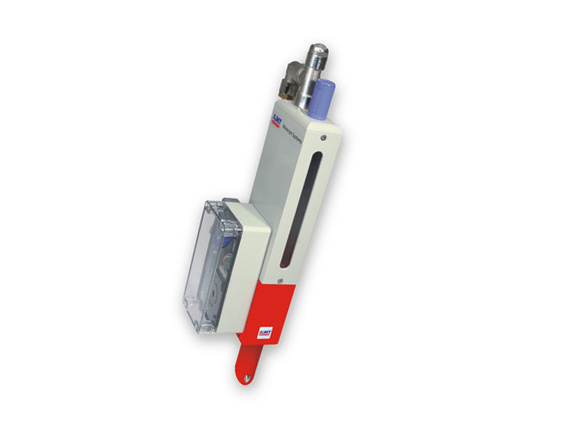

Feedline

Stable and repeatable operating parameters are a fundamental requirement for high-quality water- jet cutting. This applies in particular to abrasive applications used to cut brittle materials, where a constant flow of abrasive is simply a must.

KMT WATERJET SYSTEMS responded to this demand by developing the FEEDLINE abrasive metering system. Controlled through a central CNC controller or a potentiometer, the FEEDLINE supplies the cutting head with the optimized flow of abrasive. This helps save material and costs.

The FEEDLINE technology

The FEEDLINE system supplies the cutting head with a constant metered quantity of abrasive. Without this controlled supply, the mixing chamber for abrasive, air and water would become clogged up. With the FEEDLINE, this is effectively prevented. It feeds a metered flow of abrasive by means of compressed air into a 0.8-litre transfer tank. At the base of the tank, the abrasive collects on the metering and transfer wheel whose rotational speed determines the feed rate to the cutting head.

Lower costs thanks to accurate control

It requires different quantities of abrasive to cut different materials. The thicker the material, the more abrasive is needed. Accurate metering settings help lower operating costs especially in units used to cut many different materials on a daily basis.

The adjustment range of the FEEDLINE caters for flow rates of 0 to 1,000 g per minute. Greater quantities can be catered for by changing a shim.

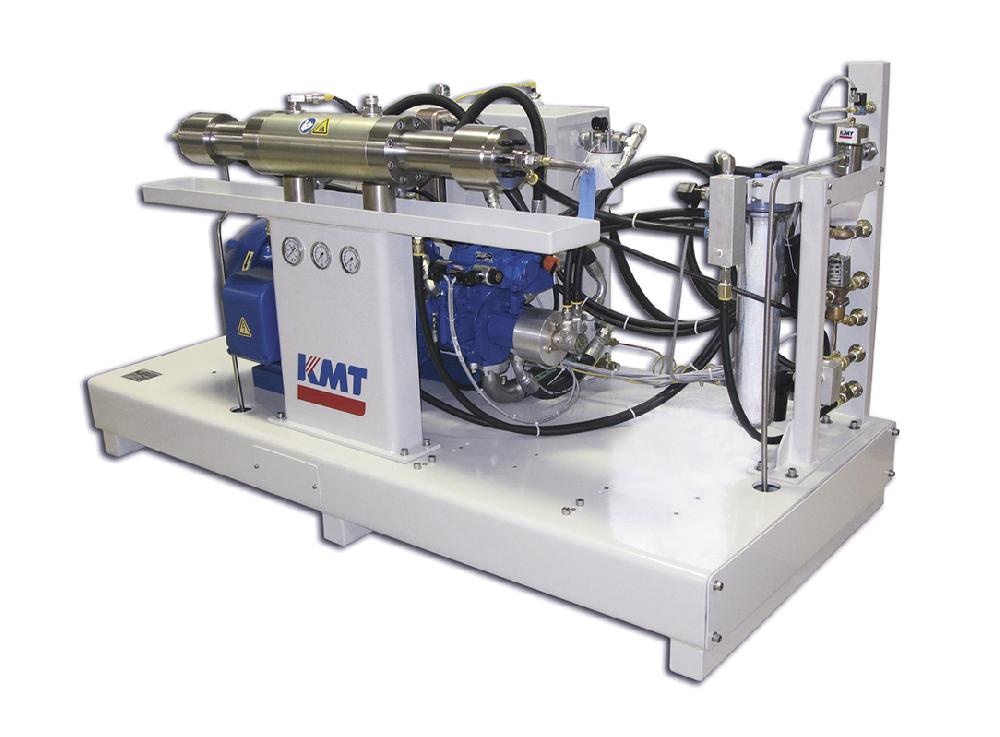

ABRASIVE MANAGEMENT SYSTEMThe abrasive metering system FEEDLINE is also available in the attractive AMS package, which additionally includes one or more abrasive cutting heads and the ABRALINE thus representing the simple complete solution for the abrasive feed. |

| FEEDLINE | |

|---|---|

| Flow rate (adjustable) | 0-1 000 g/min |

| Operating voltage | 24 VDC |

| Control voltage | 0-10 V / 4-20 V |

| Net Weight | 3,1 kg |

| Length | 124 mm |

| Width | 130 mm |

| Height | 470 mm |