BOOSTERLINE

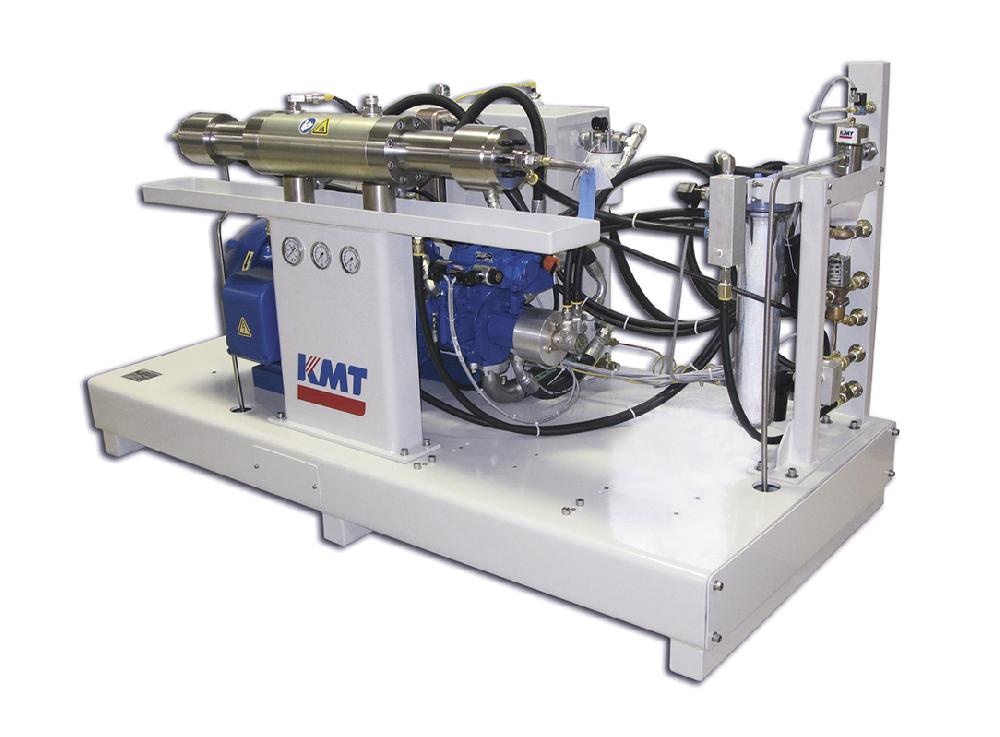

The steady cutting water supply of high pressure pumps is a significant factor when it comes to the reliability and economic efficiency of a waterjet cutting machine. the BOOSTERLINE cutting water supply system is KMT‘s innovative solution to guarantee a constant inlet pressure of the cutting water for ultra-high pressure pumps.

Constant pressure ensures safety of production

The constant supply of water to the ultra-high pressure pump through the BOOSTERLINE system prolongs the service life of wear parts in the intensifier. The maintenance interval of the intensifier and the downtimes of the cutting unit are reduced as the high pressure pump is operated at ideal conditions.

STREAMLINE™ high pressure pumps should be operated at a constant inlet pressure of 3.5 bar. Where pressure fluctuations occur in the public water supply, the BOOSTERLINE water supply system guarantees a steady volume flow to the high pressure pump. The system is automatically switched on and off, depending whether the intensifier is activated or not. Thanks to the fully automated operation, the BOOSTERLINE is very easy to operate.

On the safe side with the 750 l water tank

A tank with a capacity of 750 liters ensures that there is always sufficient water available for your cutting application. The tank is made of nontransparent high-quality plastic, preventing the growth of algae, etc. Thanks to its compact design with a square base, the tank is easy to install. It guarantees continuous water supply to the high pressure pumps. If the quality of the water from the public supply does not meet the required standard, the BOOSTERLINE can be complemented with an upstream treatment unit.

Everything under control – sensor monitoring of the fill level

To optimize the fill level of the BOOSTERLINE, it is monitored with two sensors. When the maximum fill level in the tank is reached, a 230 V solenoid valve closes the water inlet to the tank. When the water level reaches its minimum, the control system switches off the BOOSTERLINE pump, thus preventing damage from dry running. The control unit is mounted on top of the tank and is operated at 230 V.

| BOOSTERLINE | |

| Boosterline - Tank | |

| Weight | 25 kg |

| Length | 780 mm |

| Width | 780 mm |

| Height | 1600 mm |

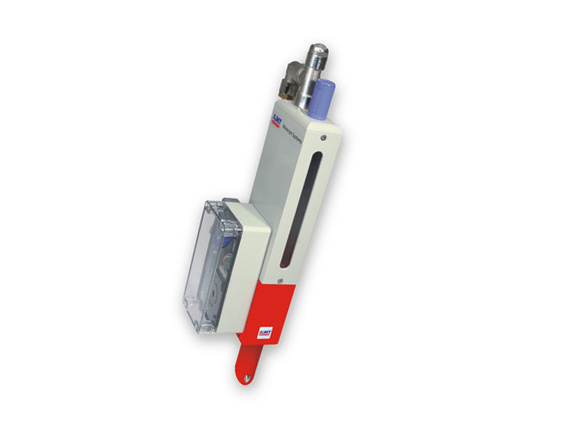

| Boosterline - Pump | |

| Weight | 10,4 kg |

| Length | 191 mm |

| Width | 504 mm |

| Height | 217 mm |

| Voltage | 230 V |

| Motor capacity | 1,5 kW |

| Max. delivery height | 45 m |

| Max. fluid quantity | 7 m3/h |

| Max. operating temperature | 40 °C |