General description |

|

|---|---|

|

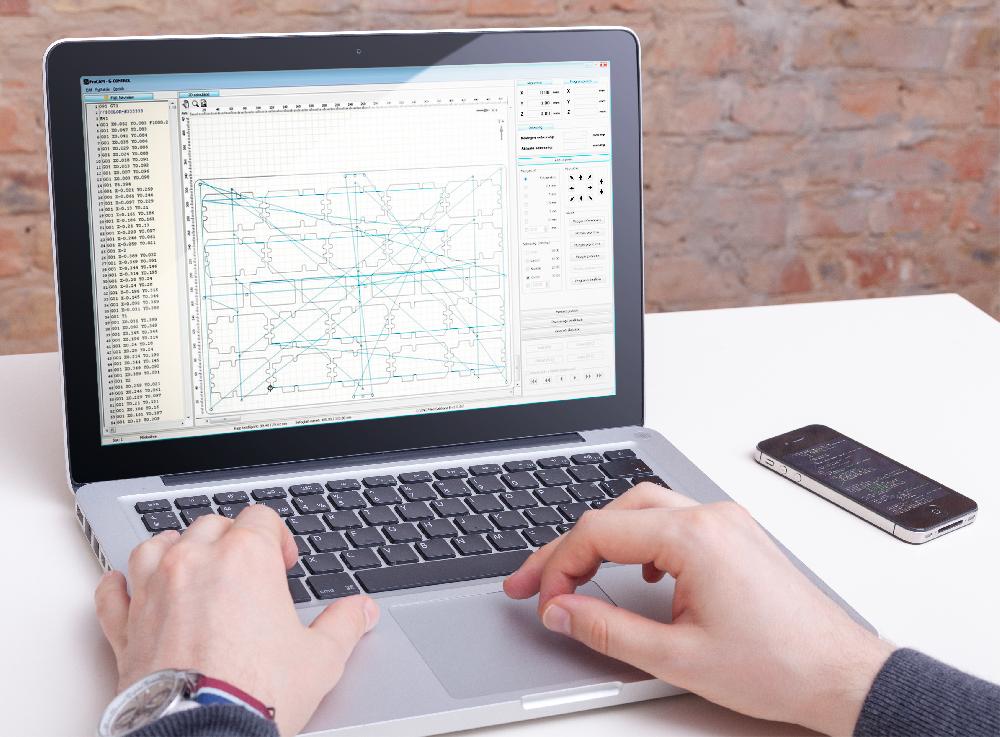

The Computer Numerical Control (CNC) is an equipment that contains a programmable microcomputer to control the process. It was created to reduce the downtime of the manual processing because preparation (like drawing) and the tool changes between each operation used to cause a significant downtime in production. By the application of computers it is possible to move along multiple axes or in a non-linear movement which is manually impossible. The control of the process is mostly defined by the software of the computer while the operation by the controlled unit and the technology applied. This built-in platform, programmable surface is the operating software of the CNC equipment, generally speaking the user interface, of which several types exist these days. Due to the user-friendly developments and the enhanced, often unique functions their standardizing does not ensure compatibility. The situation is further complicated by the fact that the individual machines can be different in their operations and functions even if their control is the same. This is possible because the general control functions are installed on a given machine by the manufacturers mainly by the PLC software which makes it possible to install special functions unique to that particular equipment. According to the technology of the operation (milling, turning, welding, whetting, waterjet, laser, etc.) the equipment can be operated with high precision at all times. |

At the same time the CNC controls several subunits:

|

Comparison Chart

| Cuttable materials |

Flame | Laser | Milling | Plasma | Waterjet |

|---|---|---|---|---|---|

| Mild steel | x | x | x | x | x |

| Carbon steel | x | x | x | x | |

| Stainless steel | x | x | x | ||

| Aluminium | x | x | x | x | |

| Titanium | x | x | x | x | |

| Chrome and cobalt alloy | x | x | x | ||

| Copper | x | x | x | x | |

| Bronze | x | x | x | ||

| Zink | x | x | x | ||

| Plexi | x | x | x | ||

| Poly carbonate | x | x | |||

| Foamed materials | x | x | x | ||

| PVC | x | x | |||

| PET | x | x | |||

| Other plastics | x | x | x | ||

| Rubber | x | ||||

| Wood | x | x | x | ||

| Marble, terazzo | x | x | |||

| Granite | x | ||||

| Glass | x |